ALLLAND Boiler Steel Pipe Supply

Welcome to Alllandsteel, a leading steel pipe manufacturer. Our UL pipe is specifically designed for fire sprinkler systems. Certified with UL Listing, it is suitable for fire protection systems in shopping malls, warehouses, logistics facilities, and similar applications. As a UL pipe supplier, we go beyond providing pipes to offer comprehensive services including specification selection and technical support, ensuring the safe implementation of fire protection piping systems.

Alllandsteel is a steel pipe manufacturer based in China with 25 years of experience. The facility spans 22,000 square meters, represents a RMB 700 million investment, and operates four production lines (JCOE, ERW, SMLS, SSAW) alongside five coating lines. With an annual production capacity of 250,000 tons, the factory covers specifications ranging from Ø406 to Ø1524 and holds multiple international certifications (API/ASTM/EN/ISO/JIS). Focused on steel pipes, creating value for you!

HOT PRODUCTS

POPULAR ARTICLES

UL Pipe refers to piping that has passed UL certification, typically fire protection piping, as UL is an international certification specifically established for fire sprinkler pipes. UL certification stipulates requirements for pipe materials, manufacturing processes, dimensions, tolerances, and more, providing safety assurance for fire protection piping. Internationally, piping with UL certification is recognized as compliant fire protection piping.

O.D.:

21.3 mm – 323.9 mm (1/2“ – 12”)

W.T.:

2.0 mm – 12.7 mm (Schedule 10 / Schedule 40)

Length:

5.8 m / 6.0 m / 11.8 m / Custom Length

Standard:

ASTM A795 / ASTM A53

Process:

ERW (Electric Resistance Welded)

Seamless (available for small diameters)

Steel Grades:

Grade A/ Grade B/

Tube Ends:

Plain End/ Grooved End/ Threaded End

Applications:

Fire Sprinkler System/ Fire Water Line/ Fire Riser System

1. Strict Raw Material Control

UL Pipe mandates the use of premium carbon steel as raw material. Only superior chemical and mechanical properties can meet fire protection piping requirements—ensuring long-term service life and resistance to impact pressure.

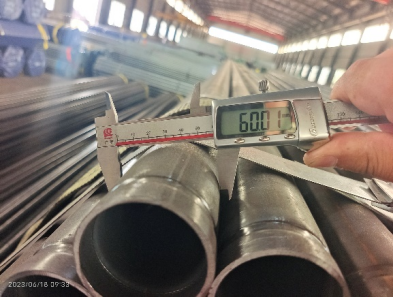

2. Rigorous Tolerance Specifications

UL Pipe enforces precise tolerances for outer diameter, wall thickness, and ovality. This ensures seamless groove connections for fire protection pipes, minimizing leakage risks.

3. Comprehensive Inspection Process

UL Pipe mandates that pipes undergo ET/UT testing, hydrostatic pressure testing, and dimensional/visual inspection.

4. Superior Surface Treatment

The standard requires pipes to feature a uniform zinc coating with strong adhesion and excellent corrosion resistance.

UL certification is a globally recognized third-party testing and certification body for fire protection piping. Its primary functions include: safety performance evaluation, production process inspection, and product compliance checks, ensuring overall factory quality and stable supply capabilities. Piping with UL certification demonstrates compliance with fire protection piping standards, enabling it to pass engineering acceptance and qualify as certified fire protection piping.

Raw Material Compliance: Chemical properties, mechanical strength, and weldability.

Weld Integrity: Verify continuous welds, consistency with base material, and stable manufacturing processes.

Pressure Resistance Testing: Comprehensive hydrostatic testing to ensure pipes withstand unexpected conditions.

UL Pipe certification is not a one-time event but involves ongoing quality oversight. Once a factory obtains UL certification, UL conducts regular on-site audits or random product sampling to verify continued compliance with standards and production of qualified products.

If a product bearing the UL Listing mark fails to meet requirements, the manufacturer may report to UL or undergo re-evaluation. Serious violations may result in revocation of UL certification.

This depends on project requirements; not all fire protection piping necessitates UL Listing certification. UL Listing-certified piping is required for North American fire protection projects, projects explicitly specified in documentation, high-rise buildings, and warehousing centers. Other projects may use piping manufactured according to project-specific requirements.

Both are inspection standards for fire protection systems, but their focuses differ:

UL Pipe emphasizes product and factory compliance, primarily for fire sprinkler piping systems.

FM Pipe leans toward insurance risk control, prioritizing the standardization of the entire piping system.

Yes, the UL Pipe we sell comes with relevant documentation, including UL certificates, specification manuals, and manufacturer instructions. These authentic and valid documents are suitable for third-party inspections.