ALLLAND Boiler Steel Pipe Supply

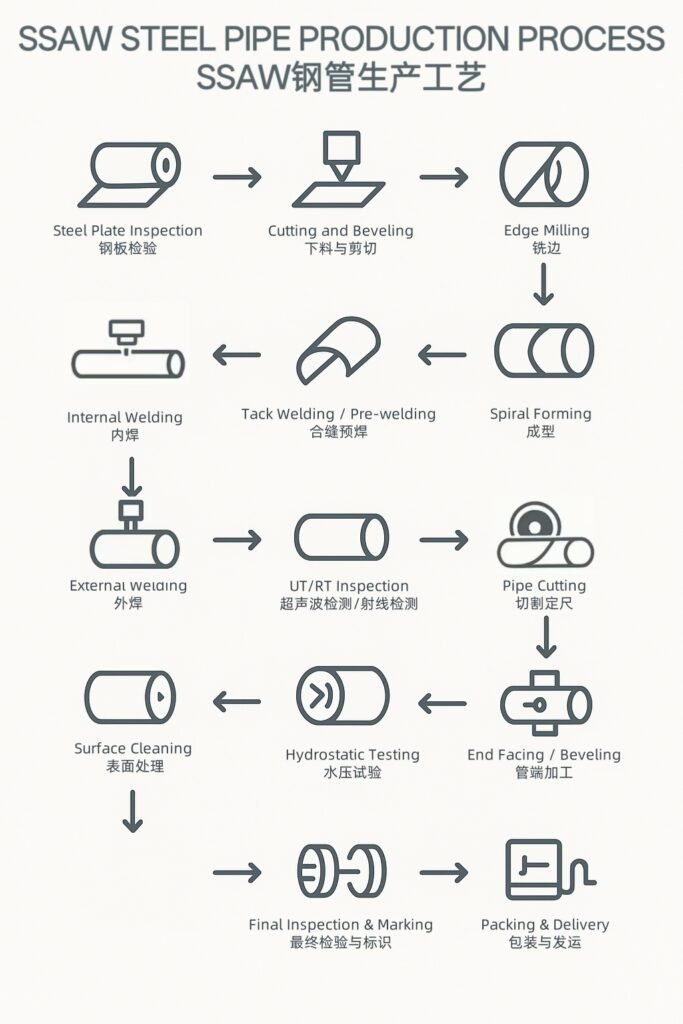

Hello, welcome to ALLLAND Steel Pipe Factory. Our SSAW pipes are widely used in oil and gas transportation, water supply and drainage, and oil and gas extraction projects. Our mature SSAW pipe production process ensures long-term stable manufacturing. Rigorous inspection procedures guarantee precise pipe dimensions, continuous and tight welds, and stable pressure-bearing capacity. All pipes are manufactured in accordance with international standards. We welcome your inquiries.

Alllandsteel is a steel pipe manufacturer based in China with 25 years of experience. The facility spans 22,000 square meters, represents a RMB 700 million investment, and operates four production lines (JCOE, ERW, SMLS, SSAW) alongside five coating lines. With an annual production capacity of 250,000 tons, the factory covers specifications ranging from Ø406 to Ø1524 and holds multiple international certifications (API/ASTM/EN/ISO/JIS). Focused on steel pipes, creating value for you!

HOT PRODUCTS

POPULAR ARTICLES

SSAW Pipe, or Spiral Submerged Arc Welded Pipe, is manufactured by spiral welding hot-rolled steel coils. The weld seam follows a spiral pattern and is exceptionally long. This pipe type features a wide diameter range and high production efficiency. It is extensively used in oil and gas transportation, municipal drainage systems, and long-distance conveyance. Particularly in cost-sensitive projects, SSAW pipe represents an excellent choice.

O.D.:

219 mm – 3000 mm (8″–120″)

W.T.:

5.0 mm – 25.0 mm

Length:

6 m / 12 m / Custom Lengths

Material:

Carbon Steel / Low Alloy Steel

Standards:

API 5L, ASTM A252, ASTM A139, GB/T 9711

Steel Grades:

API 5L Gr.B / X42 / X52 / X60 / X65 / X70

Tube Ends& Surface Treatment:

Black / Rust-proof Oil / FBE / 2LPE / 3LPE; Plain End / Beveled End

Manufacturing Process:

Spiral Welded + Submerged Arc Welding (SSAW)

SSAW Pipe Manufactured by ALLLAND

| NPS | O.D. (mm) | WT (mm) | Weight (kg/m) |

| DN300 | 323.9 | 6 | 46.9 |

| 323.9 | 8 | 62.1 | |

| 323.9 | 10 | 76.7 | |

| DN400 | 406.4 | 6 | 59.7 |

| 406.4 | 8 | 79.1 | |

| 406.4 | 10 | 97.8 | |

| DN500 | 508 | 6 | 74.8 |

| 508 | 8 | 99.1 | |

| 508 | 10 | 122.9 | |

| DN600 | 610 | 6 | 90.1 |

| 610 | 8 | 119.4 | |

| 610 | 10 | 148.1 | |

| DN800 | 813 | 8 | 159 |

| 813 | 10 | 197.6 | |

| 813 | 12 | 235.3 | |

| DN1000 | 1016 | 8 | 199.3 |

| 1016 | 10 | 247.8 | |

| 1016 | 12 | 295.5 | |

| DN1200 | 1219 | 10 | 298.2 |

| 1219 | 12 | 355.8 | |

| 1219 | 14 | 412.4 |

Water Supply and Drainage:

Capable of handling large-diameter pipelines with long service life due to corrosion-resistant coatings.

Oil and Gas Transportation:

High weld seam reliability meeting API pipeline standards at competitive pricing.

Structural Piping:

Wide range of wall thicknesses with strong load-bearing capacity. Excellent straightness for convenient construction.

SSAW pipes are manufactured using coiled steel through spiral welding, resulting in a helical weld seam. These pipes are suitable for low-pressure systems, offer fast production speeds, and are ideal for large-scale projects.

LSAW pipes utilize flat steel plates with a straight weld seam. They are suitable for medium-to-high-pressure systems, though production efficiency is lower and manufacturing costs tend to be higher.

They can be used for oil and gas transportation under certain conditions. SSAW pipes are suitable for conveying substances in low-to-medium pressure oil and gas systems or for non-trunkline applications.

Yes, anti-corrosion coatings are available. SSAW pipes typically receive external coating protection, including black paint, rust-preventive oil, FBE epoxy powder coating, 2LPE, and 3LPE corrosion protection systems. This is because SSAW pipes are frequently used in buried or exposed environments, where external coatings enhance service life. Internal coatings are only used in specific applications: transporting corrosive media, water supply and drainage projects, or conveying food-grade substances.