ALLLAND Boiler Steel Pipe Supply

Welcome to ALLLAND Steel Pipe Factory. Our OCTG products encompass tubing, casing, drill pipe, and other items, all compliant with API 5CT standards. Our pipes deliver superior quality, withstanding high temperatures, high pressures, corrosive environments, and demanding operating conditions. OCTG pipes feature high strength and reliability, ensuring long-term stable performance in downhole applications. Suitable for both onshore and offshore oil and gas projects, all pipes undergo rigorous testing. We offer a wide range of steel grades with strict wall thickness and thread specifications. We welcome your inquiries and orders.

Alllandsteel is a steel pipe manufacturer based in China with 25 years of experience. The facility spans 22,000 square meters, represents a RMB 700 million investment, and operates four production lines (JCOE, ERW, SMLS, SSAW) alongside five coating lines. With an annual production capacity of 250,000 tons, the factory covers specifications ranging from Ø406 to Ø1524 and holds multiple international certifications (API/ASTM/EN/ISO/JIS). Focused on steel pipes, creating value for you!

HOT PRODUCTS

POPULAR ARTICLES

OCTG stands for Oil Country Tubular Goods, a collective term for a category of pipes used in oil and gas extraction and transportation, encompassing oil tubing, casing, and drill pipe. OCTG pipes typically operate in high-temperature, high-pressure, or highly corrosive environments, necessitating stringent requirements for materials and manufacturing processes. The following sections detail the composition, dimensions, and performance characteristics of OCTG.

O.D.:

Common Range: 1.050“ to 20” and above (per API 5CT series)

W.T.:

Designed based on steel grade and well conditions.

Length:

R1 / R2 / R3 or fixed length

Material:

Carbon Steel / Low Alloy Steel / Corrosion-Resistant Alloy Steel

Standards:

API 5CT / ISO 11960 / GB / SY

Steel Grades:

J55, K55, N80, L80, C90, T95, P110, Q125

Tube Ends& Surface Treatment:

lain end, API threaded, Premium Connection; Bare pipe, phosphated, rust-preventive oil, painted

Manufacturing Process:

Seamless piercing + hot rolling / cold working + heat treatment

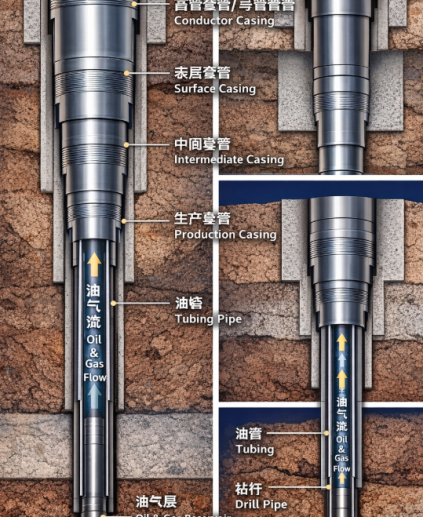

A complete OCTG system comprises casing (tophole casing, liner casing, intermediate casing, production casing), tubing, and drill pipe. The complete structure is shown in the image below.

OCTG typically employs seamless manufacturing processes, designed to withstand high-pressure conditions during extraction. Through hot rolling or cold drawing, followed by heat treatment and threading, each step is critical to ensuring the pipe’s pressure-bearing capacity and service life.

Tube Body Manufacturing: Seamless piercing process with selection of hot-rolled or cold-drawn methods. Strict control of diameter, wall thickness, and surface smoothness lays the foundation for subsequent material conveyance and pipeline longevity.

Heat Treatment: Pipes undergo normalized heat treatment followed by tempering to stabilize internal microstructure, enhancing yield strength and toughness.

Thread Processing: API threads (BTC/LTC/STC) are strictly matched to API 5CT pipe standards, with 100% thread inspection to improve sealing integrity and tensile strength, ensuring product quality.

OCTG pipes are central to oil and gas extraction. Only when pipes are safe and leak-free can risks be effectively controlled and safety incidents minimized. This section outlines OCTG pipe quality inspection, which spans the entire production process and strictly adheres to standards.

First, chemical composition analysis is conducted on incoming steel plates, pipes, or billets. Key elements—C, Mn, Cr, Mo, Ni, S, and P—are strictly controlled to ensure material stability, corrosion resistance, and toughness.

Based on steel grades and applicable standards, pipes undergo tensile tests, yield strength tests, Charpy impact tests, and other evaluations. This ensures pipes meet specification requirements and prevents operational failure risks.

High-quality OCTG pipes must exhibit zero surface or internal defects. Hidden flaws like impurities, cracks, or delamination can severely impact projects. OCTG pipes undergo comprehensive UT/MT/ET testing throughout production to guarantee internal and external integrity.

Dimensions, wall thickness, and ovality must be strictly controlled within specified tolerances. Any deviation may compromise the pipe’s pressure-bearing capacity and service life. Ensuring dimensional accuracy also facilitates installation.

Threaded connections account for the highest proportion of OCTG pipe failures. Therefore, thread inspection is critical. Threads must first be manufactured to API standards and undergo protective treatment during subsequent processing to prevent damage to the thread profile. Only threads that fully comply with standards can meet the demands of downhole operations.

The final test before pipe shipment ensures the pipe body exhibits no leakage or deformation risks under pressure.

1. Withstands Extreme Downhole Conditions

Oil and gas wells endure extreme conditions: high internal pressure, external compression forces, pipe self-weight and operational loads, and fluctuating wellbore temperatures. Conventional pipes cannot withstand these complex stresses. OCTG is engineered to account for these factors, making it uniquely suited for downhole operations.

2. Dedicated steel grades ensure operational performance

Downhole environments are diverse, encompassing shallow wells, deep wells, and highly corrosive wells. OCTG steel grades are specifically engineered to cover all well conditions, offering resistance to internal pressure, external pressure, fatigue, and corrosion.

3. High-Precision Threads

Threads play a critical role in pipeline systems, ensuring stability, leak-proof integrity, and fracture resistance during operation. Standard pipe threads fail to meet downhole requirements, whereas OCTG offers superior suitability.

4. OCTG System

OCTG constitutes a comprehensive system encompassing all quality requirements and standards for oil and gas extraction pipelines. Its components integrate seamlessly without compatibility concerns, offering greater convenience compared to alternative piping solutions.

5. Extended Service Life

While OCTG pipes carry a higher price point than other options, their advantages lie in extended service life, low failure rates, and minimal accident incidence. The value of safety far outweighs pipeline costs when weighed against potential failures and risks.