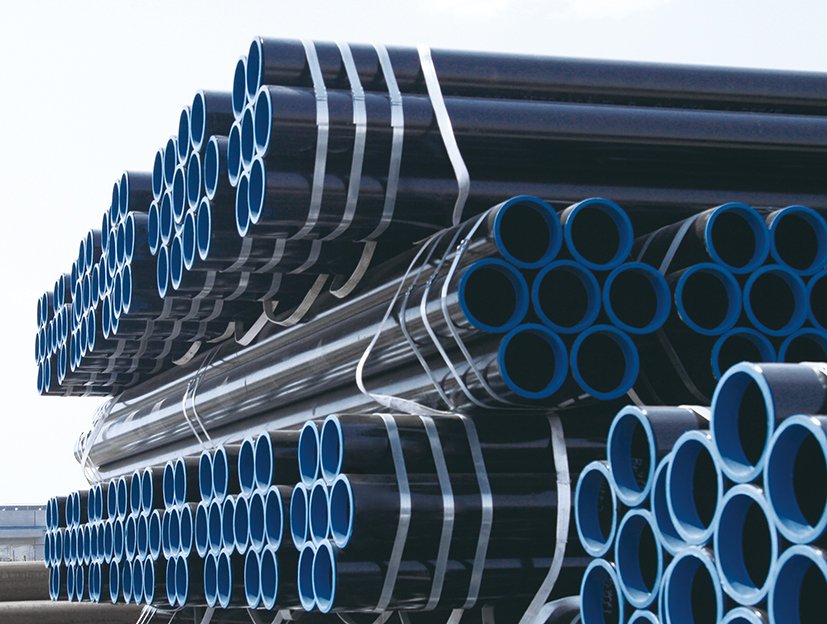

ALLLAND Boiler Steel Pipe Supply

Welcome to ALLAND. We are a professional steel pipe manufacturer certified to JIS standards, possessing the qualifications for JIS-compliant sensory production. We are capable of producing a wide range of JIS grades, covering diverse steel grades and extensive application scenarios. During production, ALLLAND strictly adheres to JIS specifications for dimensions, wall thickness, chemical composition, and mechanical properties, ensuring stable product performance and high batch consistency. All products feature full traceability, complete product markings, and comprehensive inspection reports.

Translated with DeepL.com (free version)

Alllandsteel is a steel pipe manufacturer based in China with 25 years of experience. The facility spans 22,000 square meters, represents a RMB 700 million investment, and operates four production lines (JCOE, ERW, SMLS, SSAW) alongside five coating lines. With an annual production capacity of 250,000 tons, the factory covers specifications ranging from Ø406 to Ø1524 and holds multiple international certifications (API/ASTM/EN/ISO/JIS). Focused on steel pipes, creating value for you!

HOT PRODUCTS

POPULAR ARTICLES

JIS standards, fully known as Japanese Industrial Standards, are national industrial system standard documents promulgated by the Japanese government, holding high authority in the steel, machinery, and construction industries. JIS standards not only specify the dimensions, materials, and properties of steel pipe products but also emphasize the stability and continuity of factory production.

In practical applications, steel pipes conforming to JIS standards offer enhanced safety performance and greater durability. Consequently, JIS standard steel pipes are widely used not only within Japan but also across Southeast Asian countries.

Characteristics: General structural steel tubes manufactured via hot-rolled or welded processes, typically used in construction, bridges, scaffolding, and general support structures.

Steel Grades and Mechanical Properties:

STK290 (Minimum yield strength 290 MPa)

STK400 (400 MPa)

STK490 (490 MPa)

STK500, STK540 (High-strength grades)

Specifications:

Outer Diameter: 33.4–660 mm

Wall Thickness: 2.1–22 mm

Material: Carbon steel

Process: Hot-rolled or welded pipe

Features: Excellent weldability and pressure resistance, suitable for medium- and low-pressure systems such as steam, water, and oil transportation.

Specifications:

Outer Diameter: 10.5 mm to 660.4 mm

Material: Carbon Steel

Steel Grade: STPG370, STPG410

Temperature: -15°C to 300°C

Pressure: Generally below 10 MPa

In JIS standards, steel grades are typically designated using combinations of numbers and letters. For example: “SS” denotes general-purpose carbon steel pipes, ‘STK’ indicates structural steel pipes, and “SCM” represents alloy mechanical steel pipes. Below is a detailed introduction to the characteristics of the SS series and STK series steel grades.

These are general-purpose carbon steel pipes offering good plasticity and practicality. Cost-conscious users may consider SS pipes. They find broad application in construction, support structures, and steel frameworks.

STK denotes structural steel pipes, where all grades maintain a balanced equilibrium between strength and stability. Typically, the number following “STK” indicates the minimum yield strength. These pipes are commonly used in factory structures and load-bearing components.

The JIS standard does not solely pursue individual product properties. Instead, it categorizes steel grades to balance mechanical properties, manufacturing feasibility, and final application requirements, providing comprehensive and implementable solutions for diverse scenarios and projects.

JIS standards establish stringent specifications for the chemical composition of raw materials, focusing on key elements such as carbon (C), manganese (Mn), phosphorus (P), and sulfur (S). The standards clarify the elemental composition logic, explicitly define upper limits for each element’s content, emphasize composition consistency, and ensure uniform material properties across different batches.