ALLLAND Boiler Steel Pipe Supply

Welcome to ALLAND Steel Pipe Manufacturer. Our Extruded Seamless Pipe utilizes high-quality steel billets, formed in a single extrusion process. Subsequent dimensional inspection and weld seam testing further enhance the pipe’s overall performance. This pipe is ideal for producing thin-walled, small-diameter, special alloy, or stainless steel tubing, serving industries such as natural gas, chemical processing, and machinery manufacturing. ALLLAND delivers stable, high-quality seamless pipe solutions tailored to customer requirements.

Alllandsteel is a steel pipe manufacturer based in China with 25 years of experience. The facility spans 22,000 square meters, represents a RMB 700 million investment, and operates four production lines (JCOE, ERW, SMLS, SSAW) alongside five coating lines. With an annual production capacity of 250,000 tons, the factory covers specifications ranging from Ø406 to Ø1524 and holds multiple international certifications (API/ASTM/EN/ISO/JIS). Focused on steel pipes, creating value for you!

HOT PRODUCTS

POPULAR ARTICLES

Extruded Seamless Pipe is a type of seamless steel pipe manufactured through a metal extrusion forming process. This process involves placing a heated solid steel billet into an extrusion cylinder, where high pressure forces the metal through a die to form seamless tubing with specific outer diameters and wall thicknesses.

O.D.:

20 mm – 450 mm

W.T.:

5 mm – 120 mm

Length:

2 m – 6 m, Supports non-fixed and fixed-length production

Dimensional Tolerances:

Complies with ASTM / EN / GB standards, Excellent wall thickness uniformity

Standards:

ASTM: A106, A335, A213, A269

EN: EN 10216, EN 10297

DIN: DIN 17175, DIN 2391

GB: GB/T 8162, GB/T 5310

Steel Grades:

Carbon Steel & Alloy Steel

ASTM A106 Gr.B / Gr.C

ASTM A335 P11 / P22 / P91

10CrMo9-10/ 13CrMo4-5

Surface Treatment:

As-extruded, pickled, machined surface, rust-preventive oil coating, or sandblasted

End Conditions:

Plain End (PE), Beveled End (BE), Machined End

Extruded Seamless Pipe Manufactured by ALLLAND

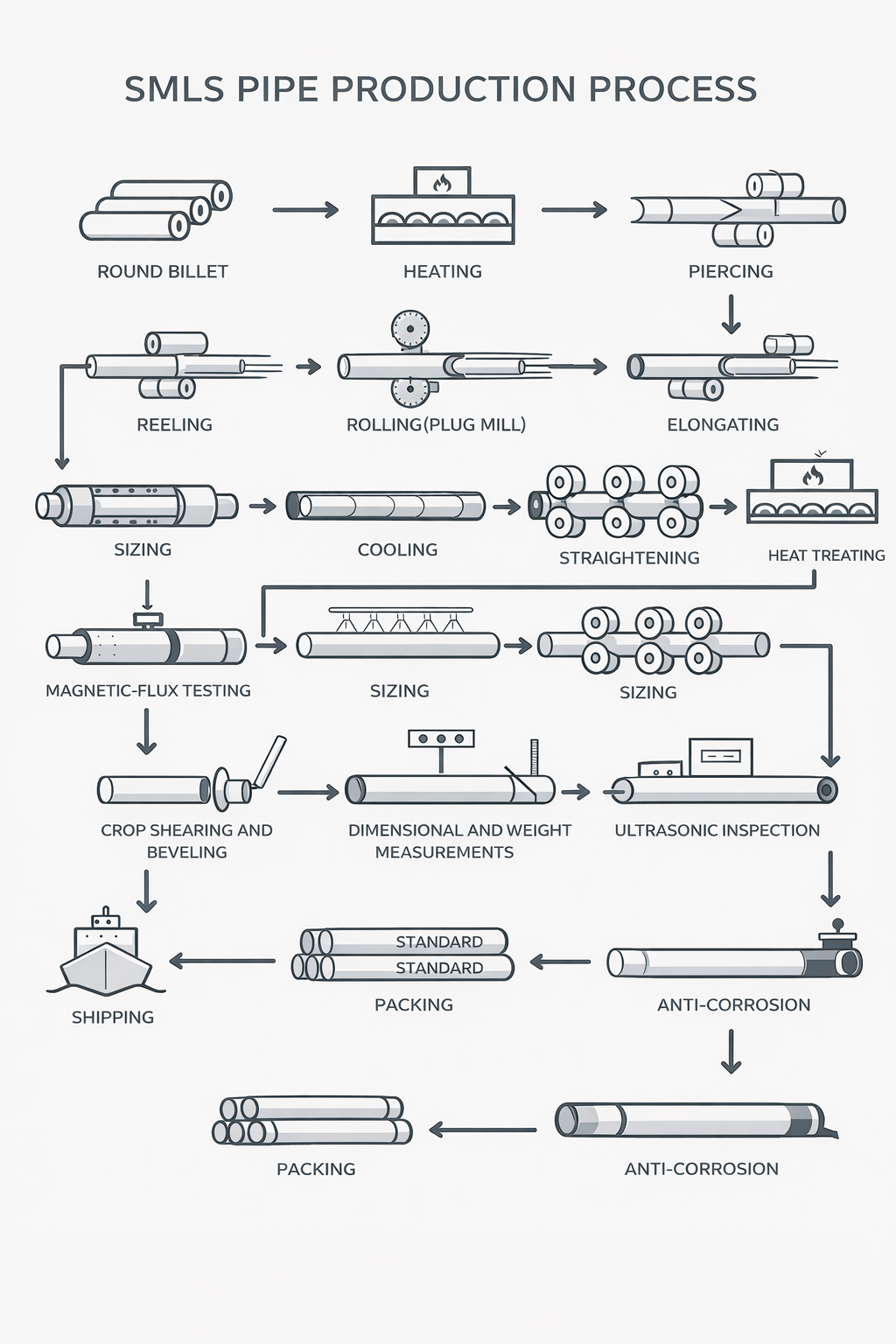

Billet heating → Extrusion forming → Cooling → Straightening → Heat treatment → Inspection → Cutting → Packaging

The billet is heated to 1100-1250°C and pierced to form the base pipe. The base pipe blank is then transported to the extrusion cylinder, where it is formed into seamless pipe of the required dimensions in a single pass under high pressure. This process features concentrated deformation and uniform stress distribution, enabling production of special dimensions.

Extruded Seamless Pipe is typically preferred when projects require:

In these scenarios, hot rolling or cold drawing processes often face limitations, whereas the extrusion process offers greater stability and controllability.

Extruded seamless steel grades cover a wide range, particularly offering distinct advantages for grades that cannot be produced via hot rolling or cold drawing processes—such as high-strength steels with high chromium or nickel content.

| Extruded Seamless Pipe Steel Grades | Typical Grades | Applicable Standards | Process Suitability | Typical Applications |

| Carbon Steel | ASTM A106 Gr.B / Gr.C | ASTM / ASME | Stable extrusion forming, suitable for thick-wall and pressure applications | High-pressure pipelines, boiler systems |

| Alloy Steel | ASTM A335 P11 / P22 / P91 | ASTM / ASME | Excellent high-temperature and high-pressure performance with dense microstructure | Power plants, superheater and steam piping |

| Stainless Steel | TP304 / TP316 / TP321 / TP347 | ASTM A312 / A213 | Extrusion process enhances plastic deformation of high-alloy steels | Chemical processing, heat exchangers, corrosive services |

| High-Temperature Stainless Steel | TP310S | ASTM A312 / A213 | Stable microstructure and strong oxidation resistance at elevated temperatures | High-temperature reaction equipment |

| Duplex Stainless Steel | UNS S31803 / S32205 (2205) | ASTM A790 | Extrusion reduces cracking risk compared to cold working | Seawater systems, chloride-containing environments |

| Other Standard Systems | — | EN 10216 / DIN / GB / JIS | Production available per project or customer specifications | Customized engineering projects |

Capable of manufacturing large-diameter, thick-walled pipes

High-alloy steel can be used as raw material

Internal voids are compacted for excellent pressure resistance

Customizable dimensions, including non-standard sizes

Seamless steel pipe extrusion is not about “the higher the grade, the better,” but rather: whether it matches the operating conditions, whether it delivers tangible structural or safety advantages, and whether it reduces overall project risks.

A professional supplier should help buyers determine “whether there are more suitable or cost-effective solutions,” rather than merely providing quotes.

| OD (mm) | Wall thickness that can be produced (mm) |

| 30 – 60 | 3 – 15 |

| 60 – 114 | 4 – 30 |

| 114 – 168 | 6 – 40 |

| 168 – 273 | 8 – 60 |

| 273 – 406 | 12 – 80 |

| 406 – 508 | 16 – 100 |

| 508 – 800 | 20 – 150 |

Extruded pipes are primarily used for structural or pressure-bearing applications, featuring heavy weight and thick walls. Specific dimensions can be calculated based on project requirements.

The range of steel grades suitable for extrusion is exceptionally broad, particularly for grades that cannot be produced via hot rolling or cold drawing processes—high-strength steels such as high-chromium and high-nickel grades demonstrate distinct advantages.

| Extruded Seamless Pipe Steel Grades | Typical Grades | Applicable Standards | Process Suitability | Typical Applications |

| Alloy Steel | ASTM A335 P11 / P22 / P91 | ASTM / ASME | Excellent high-temperature and high-pressure performance with dense microstructure | Power plants, superheater and steam piping |

| Stainless Steel | TP304 / TP316 / TP321 / TP347 | ASTM A312 / A213 | Extrusion process enhances plastic deformation of high-alloy steels | Chemical processing, heat exchangers, corrosive services |

| High-Temperature Stainless Steel | TP310S | ASTM A312 / A213 | Stable microstructure and strong oxidation resistance at elevated temperatures | High-temperature reaction equipment |

| Duplex Stainless Steel | UNS S31803 / S32205 (2205) | ASTM A790 | Extrusion reduces cracking risk compared to cold working | Seawater systems, chloride-containing environments |

| Other Standard Systems | — | EN 10216 / DIN / GB / JIS | Production available per project or customer specifications | Customized engineering projects |

Extruded seamless pipe offers a wide range of outer diameters. This process enables precise outer diameter control, achieving controllable output that meets engineering requirements.

Wall thickness exhibits excellent uniformity, eliminating localized thinning or excessive thickness in the center.

Post-production processes including sizing, hot straightening, and cold straightening when necessary effectively control ovality and straightness.

The primary distinction lies in their applicable scenarios and dimensional capabilities:

Extruded Seamless Pipe:

More suitable for thick-walled, small-ID, and specialty materials

Supports small batches and non-standard customization

Hot Rolled Seamless Pipe:

Better suited for standard specifications and high-volume production

Relatively lower cost

The decision to choose the extrusion process hinges on whether the project genuinely requires its structural and process advantages.