ALLLAND Boiler Steel Pipe Supply

Hello, welcome to ALLLAND Steel Pipe Manufacturing, specializing in the R&D and production of high-quality ERW Pipe (Electric Resistance Welded Steel Pipe). Our company operates ERW Pipe production lines, offering steel grades including ASTM A53, ASTM A106, ASTM A500, API 5L Gr.B / X42–X70, EN 10219, EN 10210, and more. Our ERW pipes support third-party inspection and can be threaded or chamfered. Various anti-corrosion treatment options are available. For inquiries, please contact us.

Alllandsteel is a steel pipe manufacturer based in China with 25 years of experience. The facility spans 22,000 square meters, represents a RMB 700 million investment, and operates four production lines (JCOE, ERW, SMLS, SSAW) alongside five coating lines. With an annual production capacity of 250,000 tons, the factory covers specifications ranging from Ø406 to Ø1524 and holds multiple international certifications (API/ASTM/EN/ISO/JIS). Focused on steel pipes, creating value for you!

HOT PRODUCTS

POPULAR ARTICLES

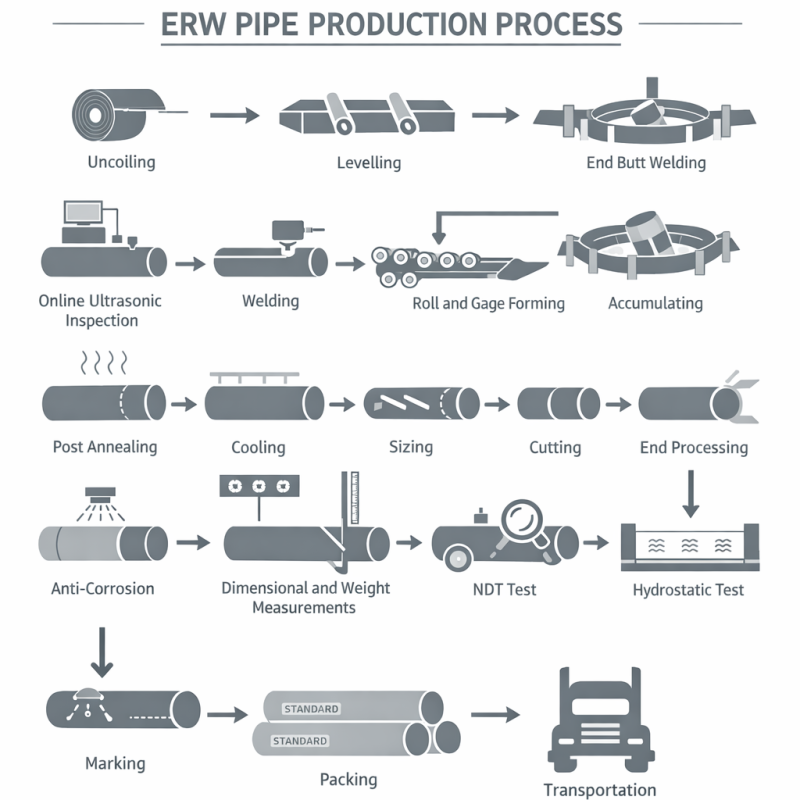

ERW Pipe stands for Electric Resistance Welded Pipe. Using high-frequency resistance welding technology, steel plates or coils are joined at their edges to form a straight weld seam along the entire length of each pipe. The ERW Pipe welding process requires no filler wire or material; instead, it utilizes heat generated by high-frequency resistance to melt the edges of the steel plates, which are then formed through compression. The weld metal structure is an integral part of the base material, resulting in more stable performance. ERW Pipe offers precise dimensions, a smooth surface, and high production efficiency. It is widely used in oil and gas transportation, construction, and water supply and drainage pipelines.

O.D.:

21.3 mm – 660 mm(1/2″ – 26″)

W.T.:

Commonly 1.0 mm – 20.0 mm

Length:

6-12m, or random lengths

Material::

Carbon steel, low-alloy steel, typically hot-rolled steel coils

Standards:

ASTM / API / EN standards are widely applicable

Steel Grades:

Gr.B / X42 / X52 / X60

Surface Treatment:

Black pipe, hot-dip galvanized, oiled, anti-corrosion coating

Pipe Ends: :

Plain End, Beveled End, Threaded End

First, the stability of steel pipes is not solely dependent on dimensions; selecting the appropriate material is equally crucial. Below, we will discuss the steel grades and material selection for ERW pipes.

ERW pipes typically utilize hot-rolled steel strips made of carbon steel or alloy steel. The advantages of hot-rolled steel strips include: uniform chemical composition, suitability for continuous electric welding forming, and excellent surface quality, resulting in smooth and durable pipes. Carbon steel remains the most commonly used material at present. Carbon steel ERW pipes are suitable for transporting most fluids and offer greater cost-effectiveness.

Welded pipes demand strict chemical composition control, particularly in the weld zone. Proper chemical composition ensures stronger welds and longer pipe service life. Below are key chemical elements affecting pipe toughness:

· C (Carbon): Affects strength and weldability

· Mn (Manganese): Enhances strength and toughness

· S / P (Sulfur / Phosphorus): Strictly limited to prevent weld embrittlement

· Nb / V / Ti (Microalloying elements): Used in API high-strength grades

| Standard | Steel Grade |

| API 5L | PSL1/PSL2 · Gr.A, Gr.B, X42 – X80 |

| API 5CT | J55, K55, N80, L80 (For Casing & Tubing) |

| ASTM A53 / A179 / A500 / A252 | Gr.A, Gr.B, Gr.C |

| EN 10217 / EN 10219 / EN 10255 | S275JR, S275J0H, S355JRH, S355J2H |

| AS/NZS 1163 | C250, C350, C450 |

| GOST 3262 | St2kp, St3kp |

| BS 1387 / UL / FM | For Fire-Fighting & Water Distribution Systems |

Notes:

1. Steel selection requires attention to chemical composition, particularly elements such as C, Mn, S, and P.

2. Post-weld heat treatment of the weld zone enhances performance.

3. Ultrasonic testing is required after pipe forming to prevent nonconforming products.

4. Final steps include chemical composition analysis, mechanical property testing, and hydrostatic pressure testing.

5. Products must be marked with traceable information such as furnace number, standard, and steel grade.

Black Pipe: Untreated, suitable for secondary processing or short-term use

Oil Pipe: Coated with rust-preventive oil, suitable for transportation or storage rust prevention

Hot-dip galvanizing: Suitable for outdoor or humid environments

Epoxy / FBE Coating: Enhances pipeline corrosion resistance

3LPE / 3LPP: Used for oil and gas extraction/transportation or underground pipeline projects

Internal Coating: Reduces media corrosion and resistance, minimizes internal scaling

Special Environments: Develop feasible protection solutions, especially for marine and high-salt-fog environments.

Standard Packaging: Bundled with steel strapping, pipe ends protected with caps. Additional paper layers may be added for certain pipes.

Transportation: Primarily shipped via container, adaptable to customer requirements.

Delivery: On-time delivery with required markings, accompanied by MTC certificates.