ALLLAND Boiler Steel Pipe Supply

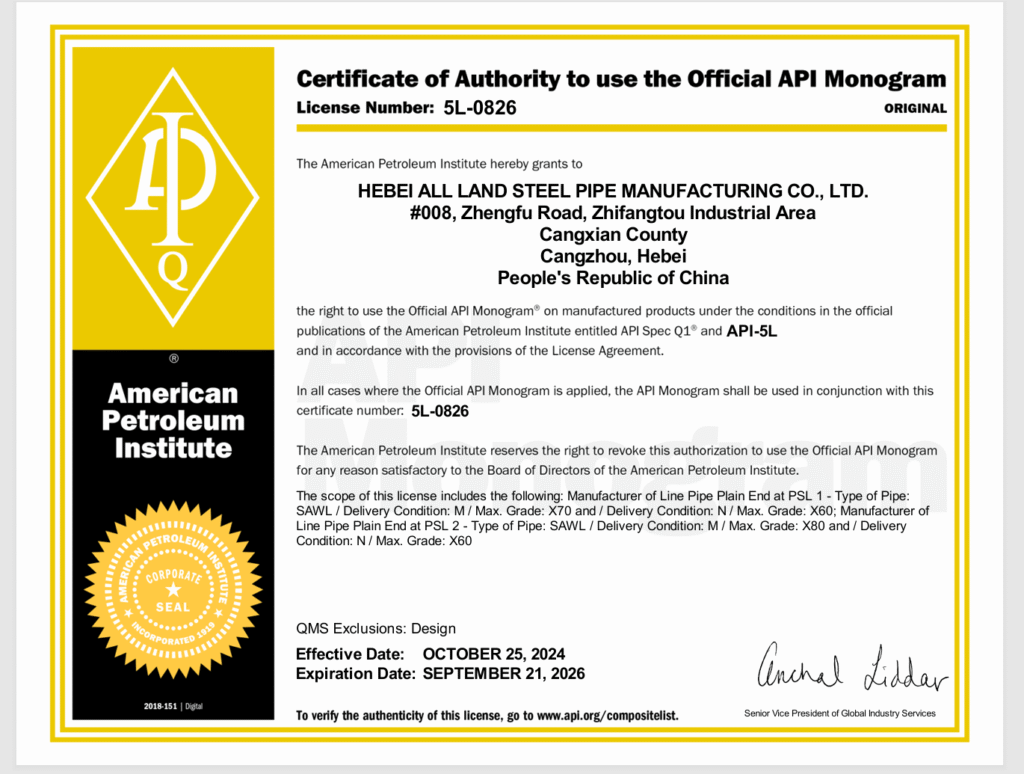

ALLLAND Steel Pipe Factory holds API pipeline certification and possesses the capability to undertake large-scale projects. Equipped with three production lines, ALLLAND manufactures API-certified spiral welded pipes, straight seam welded pipes, and seamless steel pipes. Leveraging advanced production techniques and comprehensive testing capabilities, all steel pipes sold are certified products. Currently, our products are widely applied in long-distance pipelines, offshore platforms, chemical equipment, and other fields. We look forward to collaborating with you.

Alllandsteel is a steel pipe manufacturer based in China with 25 years of experience. The facility spans 22,000 square meters, represents a RMB 700 million investment, and operates four production lines (JCOE, ERW, SMLS, SSAW) alongside five coating lines. With an annual production capacity of 250,000 tons, the factory covers specifications ranging from Ø406 to Ø1524 and holds multiple international certifications (API/ASTM/EN/ISO/JIS). Focused on steel pipes, creating value for you!

HOT PRODUCTS

POPULAR ARTICLES

API, the American Petroleum Institute, stands as one of the most authoritative technical standards organizations globally for the petroleum, natural gas, and other energy industries. API standards primarily define specifications for steel pipes and equipment used in oil and gas extraction, holding particular authority in the OCTG and line pipe sectors.

In steel pipe production, API standards define the physical and chemical properties of pipelines, including: resistance to high temperatures and pressures, corrosion resistance, chemical composition control, connection methods, tolerances, and process traceability. This ensures that API-compliant steel pipes offer greater practicality and safety compared to ordinary structural steel pipes.

For steel pipe manufacturers, API certification serves as a passport to the international market. Manufacturers holding API certification demonstrate rigorous quality control and testing systems, representing a key technological threshold in the oil and gas industry. API-certified steel pipes are approved for use in international oil and gas projects.

Unlike other standards, API specifications are primarily tailored for the oil and gas sector. ASTM standards cover a broader range, particularly excelling in structural piping, while EN standards are predominantly used for construction and scaffolding piping. Consequently, the oil and gas industry widely adheres to API standards, with other standards serving primarily as supplementary requirements for regional compliance.

This standard is widely used in oil and gas transportation, primarily involving seamless and welded pipe production processes, suitable for long-distance applications. Common steel grades include: PSL1: B, X42, X46, X52, X60, X65, X70; and PSL2, which adds stricter inspection requirements based on PSL1.

This standard represents one of the technically advanced and production-demanding specifications in the oil and gas industry, primarily applied in extraction and transportation projects. Common steel grades include: J55/K55/L80/C90/P110, etc. It categorizes pipes into casing and tubing types, used within natural gas extraction wells. These pipes withstand high-temperature, high-pressure, and highly corrosive environments.

API standards encompass more than just dimensional, strength, and chemical property specifications—they constitute a comprehensive steel pipe production system. Every stage, from raw materials to manufacturing, inspection, and traceability, is governed by standardized regulations. This not only provides customers with verifiable benchmarks but also establishes production standards for pipe manufacturers, fostering greater transparency throughout the entire transaction process.