ALLLAND Boiler Steel Pipe Supply

Allland holds AS/NZS certification, ensuring our compliance with Australian and New Zealand standards and requirements throughout raw material procurement, manufacturing processes, and product inspection. We consistently produce steel pipes meeting AS/NZS 1163/1074/1579 standards, distributing them to numerous countries worldwide. Our stringent quality control guarantees dimensional tolerances remain within specified limits.

All our steel pipes are traceable, and every product comes with inspection reports and relevant technical certificates to guarantee quality.

Alllandsteel is a steel pipe manufacturer based in China with 25 years of experience. The facility spans 22,000 square meters, represents a RMB 700 million investment, and operates four production lines (JCOE, ERW, SMLS, SSAW) alongside five coating lines. With an annual production capacity of 250,000 tons, the factory covers specifications ranging from Ø406 to Ø1524 and holds multiple international certifications (API/ASTM/EN/ISO/JIS). Focused on steel pipes, creating value for you!

HOT PRODUCTS

POPULAR ARTICLES

AS/NZS standards, formally known as Australian/New Zealand Standards, constitute a joint technical specification system for steel pipes developed and published by Australia and New Zealand. Widely adopted across both regions, these standards define pipe dimensions, materials, mechanical properties, manufacturing processes, and applications. Compliance with AS/NZS certification is mandatory for steel pipe products entering the Australian and New Zealand markets.

The development of AS/NZS standards thoroughly considers local environmental characteristics: coastal regions, highly corrosive environments, and building safety regulations. Consequently, compared to other internationally recognized standards, AS/NZS standards offer superior durability and applicability. Core standards include: AS/NZS 1163 (Structural Hollow Sections), AS/NZS 1074 (General Purpose Steel Tubes), and AS/NZS 1574. AS/NZS standards represent not only market access requirements but also a reflection of a company’s comprehensive capabilities.

AS/NZS 1163 – Structural Steel

One of the most critical standards in Australia and New Zealand, this specification covers structural steel primarily used for building support functions. It includes three cross-sectional forms: circular, square, and rectangular. Typically manufactured using welding processes, the standard defines product dimensions, cross-sections, surface characteristics, and performance metrics. The most commonly used grades are C250 and C350, with this standard widely applied in construction and large-scale engineering projects.

AS/NZS 1074 – Pipes and Fittings

This standard establishes technical specifications for steel pipes and fittings, defining specific dimensions and performance requirements for pipelines used in transportation applications. Compared to other standards, it offers greater versatility and exceptional cost-effectiveness.

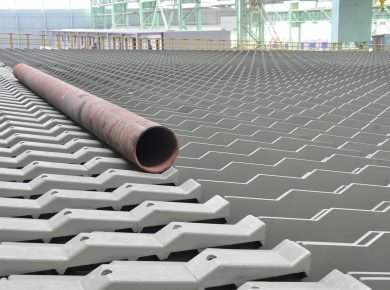

AS/NZS 1579 – Scaffolding Tubes

This standard explicitly defines the outer diameter, wall thickness, mechanical properties, load-bearing capacity, and surface quality of steel tubes used for scaffolding. Pipes conforming to this standard can be repeatedly assembled and reused, offering exceptional durability.

Material Requirements

Chemical Composition Requirements (C/Mn/P content, etc.)

Alloying Element Requirements

Weldability Requirements

Mechanical Property Requirements

Yield Strength

Tensile Strength

Elongation

Impact Resistance

Ductility Requirements

Manufacturing Process Requirements

Dimensions (OD, Wall Thickness, Length)

Tolerance Range

Straightness

Ovality

Inspection Requirements

Chemical Composition Analysis

Mechanical Property Testing (Flattening, Impact, Tensile)

Non-Destructive Testing

Factory Quality Documentation