ALLLAND Boiler Steel Pipe Supply

ALLLAND’s API Thread products strictly adhere to API standards, meeting specifications such as API 5B, API 5CT, and API 5L for use in oil pipes, casing, drill pipes, and more. These API Threads offer advantages including high precision, diverse dimensions, multiple steel grades, and comprehensive protective measures, making them highly favored in international projects. All our API Threads undergo rigorous inspection to ensure clear furnace temperature profiles, standard-compliant taper angles and pitch dimensions, guaranteeing smooth on-site installation.

Alllandsteel is a steel pipe manufacturer based in China with 25 years of experience. The facility spans 22,000 square meters, represents a RMB 700 million investment, and operates four production lines (JCOE, ERW, SMLS, SSAW) alongside five coating lines. With an annual production capacity of 250,000 tons, the factory covers specifications ranging from Ø406 to Ø1524 and holds multiple international certifications (API/ASTM/EN/ISO/JIS). Focused on steel pipes, creating value for you!

HOT PRODUCTS

POPULAR ARTICLES

API Thread is a specialized thread for oil and gas pipelines conforming to American Petroleum Institute standards, primarily used in petroleum and natural gas extraction and downhole operations. Its defining feature is the API-standard thread at the pipe end, enabling rapid connection of casing and tubing with high reliability and excellent sealing performance. Manufactured to standards, it offers enhanced compatibility and meets specifications such as API 5CT. It is widely adopted across the global oil and gas industry.

Strict compliance with international standards such as API 5B, API 5CT, and API 5L

Excellent torque resistance and mechanical strength

Reliable threaded structure enabling airtight or non-airtight connections

Widest-used standard compatible with most pipeline systems

Sealing achievable via thread lubricants, sealing rings, etc.

Commonly used in oil and gas extraction for easy field installation.

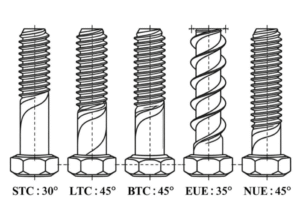

API Threads represent the most widely used thread standard in oil and gas pipelines, encompassing STC, LTC, BTC, NUE, EUE, API REG, IF, and NC series threads. These standards cover all specifications required for casing, tubing, and drill pipes. They offer unified standards, easy installation, and excellent compatibility.

Different pipelines utilize specific thread types, and the characteristics and distinctions of each thread are categorized below.

API STC

API LTC

API BTC

API NUE

API EUE

API Regular / IF / NC

Among these, the mandrel process is optimal for boiler tube manufacturing. This method involves elongating the billet in a multi-stand machine to reduce wall thickness, ensuring surface quality and uniform wall thickness.

As an OCTG pipe manufacturer, our facility possesses advanced API thread processing technology, enabling comprehensive pipeline production and machining workflows.