ALLLAND Boiler Steel Pipe Supply

Hello, welcome to Allland Steel Pipe Factory. Our LSAW pipes are manufactured using premium steel plates, featuring a smooth surface and a structurally sound interior, produced through double-sided submerged arc welding. Pipe production adheres to international standards such as API, ASTM, EN, and GB, ensuring high-quality pipes at competitive prices below market rates. Below is an introduction to our LSAW pipes.

Alllandsteel is a steel pipe manufacturer based in China with 25 years of experience. The facility spans 22,000 square meters, represents a RMB 700 million investment, and operates four production lines (JCOE, ERW, SMLS, SSAW) alongside five coating lines. With an annual production capacity of 250,000 tons, the factory covers specifications ranging from Ø406 to Ø1524 and holds multiple international certifications (API/ASTM/EN/ISO/JIS). Focused on steel pipes, creating value for you!

HOT PRODUCTS

POPULAR ARTICLES

What is an LSAW pipe? LSAW pipe, short for Longitudinal Submerged Arc Welded pipe, is a type of welded pipe manufactured by rolling steel plates longitudinally into pipe blanks and then welding them using the submerged arc welding process. It primarily produces large-diameter, thick-walled welded pipes with certain pressure-bearing capabilities. Manufactured to international or domestic standards such as ASTM, API, EN, DIN, and GB/T, it finds extensive application in fluid transportation, high-pressure chemical processing, and related industries.

O.D.:

219 mm – 1420 mm (larger diameters available upon request)

W.T.:

6 mm – 40 mm (heavier walls available upon request)

Length:

6 m – 12 m (Custom lengths available)

Material:

Q235, Q345, X42, X52, X60, etc.

Standards:

ASTM A106, ASTM A53, API 5L, EN 10219 / EN 10210, GB/T 9711

Steel Grades:

Gr.B, X42, X52, X60, P235, P355, etc.

Tube Ends& Surface Treatment:

Black pipe, hot-dip galvanized, oil-coated rustproof; Plain End, Threaded End, Beveled End.

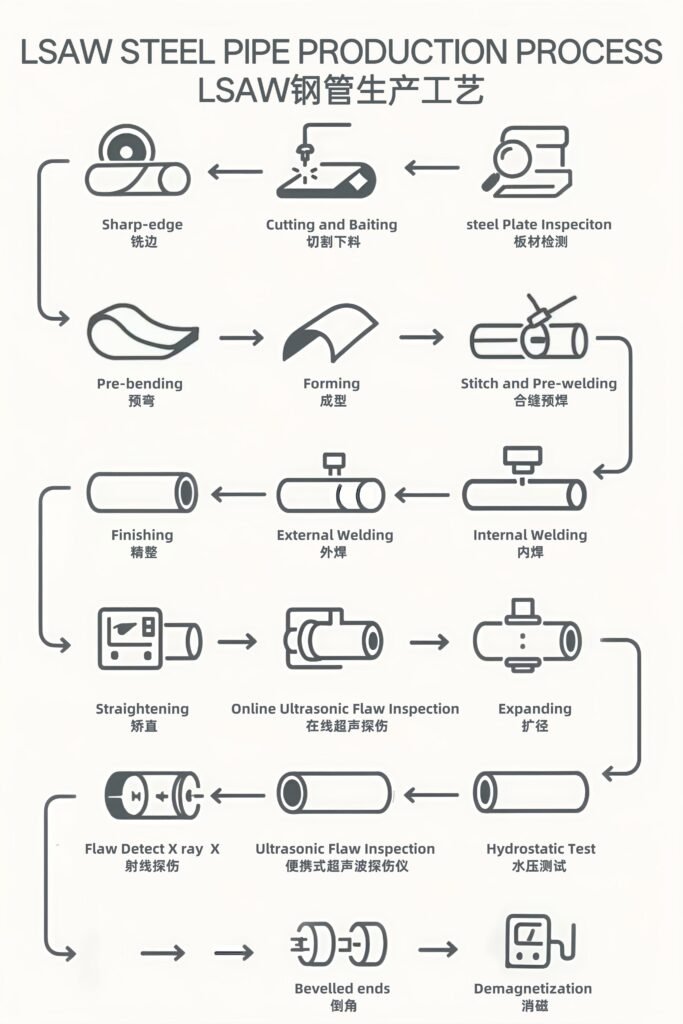

Manufacturing Process :

Longitudinal rolling of steel plate → LSAW → Straightening → End processing → Inspection

LSAW Manufactured by ALLLAND

In actual engineering procurement, the reference criteria for LSAW pipes extend beyond just outer diameter and price. Wall thickness, steel grade, and specific application scenarios must also be considered. ALLLAND’s LSAW pipes range from 219 mm to 1420 mm in outer diameter. Below, we analyze the characteristics and applications of LSAW pipes from these three perspectives.

Outer Diameter: 219 mm – 508 mm; Wall Thickness: 6 mm – 12 mm

Features: Easy construction, cost-effective

Applications: Urban water supply/drainage, industrial conveyance, general pressure oil/gas pipelines

Outer Diameter: 508 mm – 1016 mm; Wall Thickness: 10 mm – 25 mm

Characteristics: High transport efficiency, robust pipeline

Applications: Long-distance oil and gas transmission, urban water supply trunk lines, high-pressure pipelines

Outer Diameter: 1016 mm and above; Wall Thickness: 20 mm – 40 mm

Characteristics: High material requirements, stringent inspection

Applications: High-pressure oil and gas trunk lines, major energy projects, and cross-regional transmission.

1. The longitudinal rolling process of steel plates determines the pipe dimensions and ovality.

2. The welding process employs double-sided welding on both inner and outer surfaces, focusing on critical control points to ensure pipe consistency.

3. 100% UT/RT coverage guarantees pipeline qualification.

4. Supports third-party inspections and random sampling.

5. Our technical team can customize pipelines per your requirements, assisting with material selection and outer diameter specifications.

6. Full traceability throughout the pipeline production process.

Due to their large diameter and weight, LSAW Steel Pipe products are carefully secured during transport using custom saddles, anti-deformation supports, and end protectors. Depending on project volume and distance, three major logistics methods are applied to ensure the safe delivery of each LSAW Steel Pipe shipment.

The minimum order quantity generally depends on the pipe type, diameter, and wall thickness. For standard-sized products, the minimum order quantity is relatively low. You can directly submit an inquiry, and we will contact you within 8 hours.

Generally yes. For large diameters, LSAW pipes offer faster production and lower material loss, making them relatively more cost-effective.

Yes. Selecting corrosion-resistant steel grades or applying coatings to the pipes can effectively prevent corrosion and extend their service life.