ALLLAND Boiler Steel Pipe Supply

Welcome to Alllandsteel Pipe Company. Our SMLS pipes are manufactured using hot-rolled and cold-drawn processes, ensuring precise dimensions and a smooth, burr-free surface. High-quality raw materials provide superior pressure resistance and extended service life. SMLS pipes are suitable for natural gas, boiler systems, power generation, and chemical processing applications. We strictly adhere to international production standards including ASTM, API, EN, and DIN. Our rigorous inspection procedures ensure pipe quality while offering competitive pricing. We welcome your inquiries and orders.

Alllandsteel is a steel pipe manufacturer based in China with 25 years of experience. The facility spans 22,000 square meters, represents a RMB 700 million investment, and operates four production lines (JCOE, ERW, SMLS, SSAW) alongside five coating lines. With an annual production capacity of 250,000 tons, the factory covers specifications ranging from Ø406 to Ø1524 and holds multiple international certifications (API/ASTM/EN/ISO/JIS). Focused on steel pipes, creating value for you!

HOT PRODUCTS

POPULAR ARTICLES

SMLS stands for Seamless Steel Pipe, manufactured through a single-step piercing process from a pipe blank without any breaks or welded seams. It is typically produced using either hot-rolling or cold-drawing techniques. Cold-drawn processes are employed for small-diameter pipes to achieve greater dimensional precision; while large-diameter pipes utilize hot-rolling. Compared to pipes produced by other methods, SMLS Pipe offers superior pressure resistance and structural uniformity. It is applied in environments demanding high pressure and temperature tolerance.

O.D.:

10.3 mm – 660 mm (Standard ≤ 426 mm)

W.T.:

1.5 mm – 50 mm

Length:

Fixed Length 5–12 m / Random Length

Material:

Carbon Steel / Alloy Steel

Standards:

ASTM / ASME / EN / DIN / GB

Steel Grades:

ASTM A106 Gr.B / A53 Gr.B / A333 Gr.6 / API 5L Gr.B / X42–X60

Tube Ends& Surface Treatment:

Black, Pickled, Oiled, Rustproofed;Plain End (PE), Beveled End (BE), Threaded End (TE)

Manufacturing Process:

Hot-Rolled Seamless, Cold-Drawn Seamless, Hot-Expanded Seamless

SMLS Pipe Manufactured by ALLLAND

| NPS | O.D. (mm) | W.T. (mm) | Weight(kg/m) |

| 1/2″ | 21.34 | 2.77 | 1.27 |

| 3/4″ | 26.67 | 2.87 | 1.68 |

| 1″ | 33.4 | 3.38 | 2.5 |

| 1-1/4″ | 42.16 | 3.56 | 3.39 |

| 1-1/2″ | 48.26 | 3.68 | 4.05 |

| 2″ | 60.33 | 3.91 | 5.44 |

| 2-1/2″ | 73.03 | 5.16 | 8.63 |

| 3″ | 88.9 | 5.49 | 11.29 |

| 4″ | 114.3 | 6.02 | 16.07 |

| 5″ | 141.3 | 6.55 | 21.77 |

| 6″ | 168.28 | 7.11 | 28.26 |

| 8″ | 219.08 | 8.18 | 42.55 |

| 10″ | 273.05 | 9.27 | 60.31 |

| 12″ | 323.85 | 9.53 | 73.79 |

| 14″ | 355.6 | 9.53 | 81.99 |

| 16″ | 406.4 | 9.53 | 93.3 |

Dimensions comply with common seamless pipe standards such as ASTM A106 / A53 / API 5L.

Weight calculations use a carbon steel density of 7.85 g/cm³.

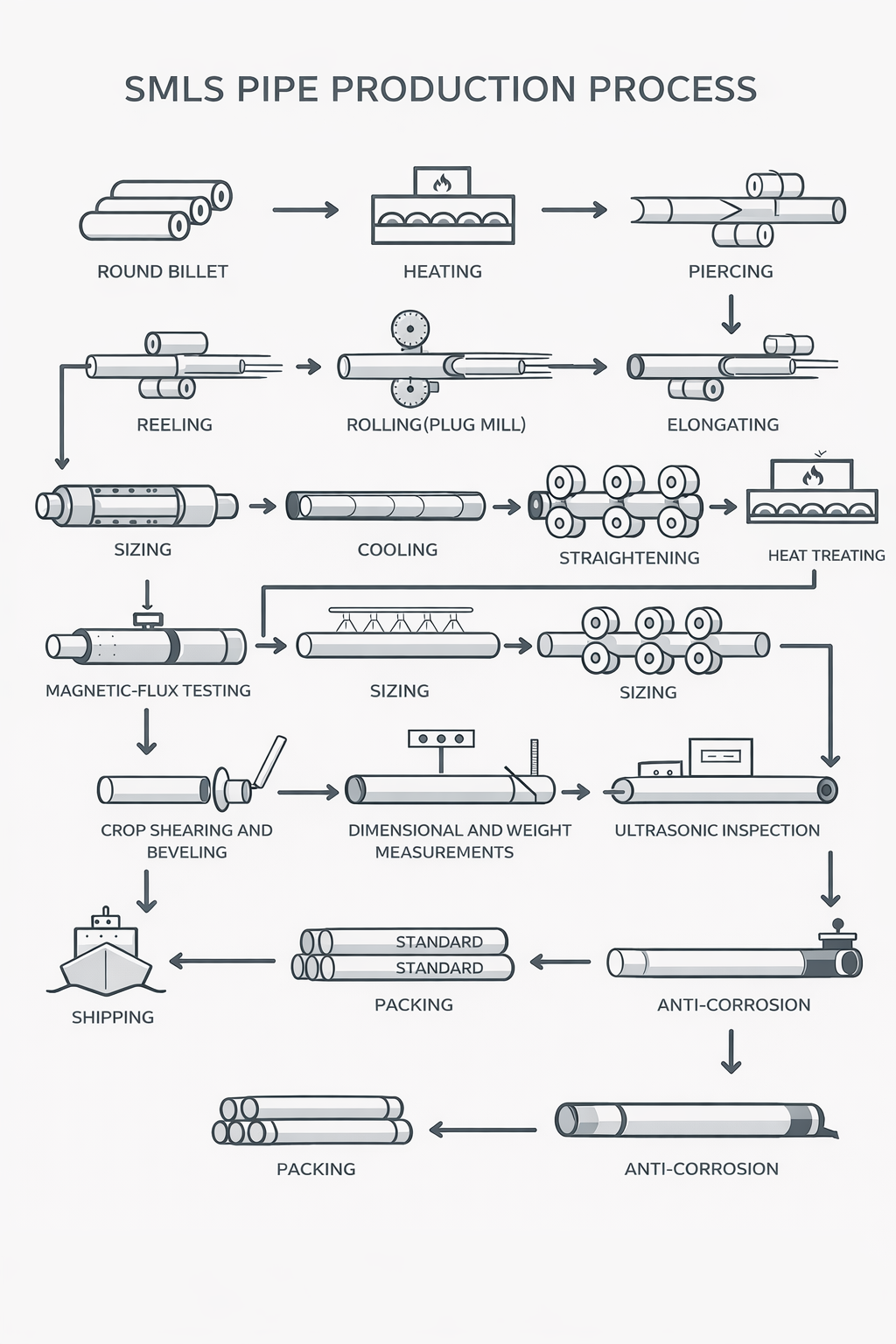

1. Raw Material Preparation:

Chemical composition meets standards; internal structure is dense and free of cracks.

2. Material Inspection:

Chemical analysis and visual inspection conducted prior to production.

3. Heating Process:

Heated to 1100-1208°C to enhance material plasticity.

4. Piercing:

Hollow pipe formed via machine piercing. This critical step directly impacts the pipe’s pressure-bearing capacity and practicality.

5. Rolling Forming

Dimensions and diameter are stabilized using a continuous rolling mill to ensure pipes remain within tolerance limits.

6. Cold Drawing

Secondary processing after hot rolling refines the pipe surface for greater smoothness and dimensional accuracy.

7. Hot Expansion

Expands the diameter of small-caliber pipes.

8. Sizing

Machine sizing refines pipe diameter and ovality while eliminating residual stresses.

9. Heat Treatment

Processes like normalizing, annealing, and quenching relieve stresses and enhance product stability.

10. Cutting

Lengths are cut to specification, and pipe ends are machined.

11. Surface Treatment

Common methods include black skin, pickling, oil coating, and temporary corrosion protection.

Among these, the mandrel process is optimal for boiler tube manufacturing. This method involves elongating the billet in a multi-stand machine to reduce wall thickness, ensuring surface quality and uniform wall thickness.

| Application | Application Scenarios | Standards | Steel Grades | Core Reasons for Selecting SMLS |

| Oil and Gas | High-pressure oil and gas transportation, compressor station pipelines | API 5L / ASTM A106 | Gr.B、X42、X52、X60 | High pressure resistance with extended service life |

| Boilers and Steam Systems | Boiler tubes, steam conveyance | ASTM A106 / ASTM A335 / EN 10216 | Gr.B、P11、P22 | Withstands high temperatures and pressures, seamless construction for enhanced safety and reliability |

| Chemical and Petrochemical Engineering | Process piping, pressure vessel connecting pipes | ASTM A106 / EN 10216 | Gr.B、16Mo3 | Resists corrosive media with stable structural integrity |

| Power and Energy Engineering | Power plant high-pressure feedwater pipes, steam systems | ASTM A106 / ASTM A335 | Gr.B、P22 | Exceptional pressure tolerance for demanding environments |

| Fire Protection and Safety Systems | Advanced fire protection systems | ASTM A106 / ASTM A53 | Gr.B | High reliability suitable for critical safety systems |

| Machine Manufacturing | Mechanical structural components, engineering equipment | ASTM A106 / EN 10297 | E355 | Precision dimensions with excellent machinability |

| Hydraulic and Pressure Systems | Hydraulic lines, high-pressure conveyance systems | ASTM A106 / DIN 2391 | St52 / E355 | Dense internal structure delivers superior pressure resistance |

Not necessarily. Seamless pipes can operate normally under high temperature and pressure conditions, but they come with higher production costs and stricter material requirements. Therefore, welded pipes can be used in applications without pressure or high-temperature demands, offering greater cost-effectiveness.

Yes. Seamless pipes produced by ALLLAND can be finished with straight ends, beveled ends, or threaded ends, eliminating the need for secondary processing.

The need for heat treatment depends on the piping standards and application. In demanding environments, heat treatment is recommended to maximize piping performance.

Three heat treatment processes exist: annealing, normalizing, and quenching + tempering. Each serves distinct purposes:

Annealing: Eliminates material stress and enhances ductility, primarily used in cold drawing processes.

Normalizing: Uniforms internal structure and improves material properties. Used for pressure-bearing fluid pipelines.

Quenching + Tempering: Rapid cooling followed by reheating. Eliminates material brittleness and enhances pressure resistance. Used for high-temperature, high-pressure pipelines.